Yachiyo Special Metal Co., Ltd. is dedicated in the toll rolling and after processing of specialty steel and non-ferrous alloyed metal.

日本語 | English

TEL. +81-47-459-2211

730, Owadashinden, Yachiyo, Chiba prf., Japan

Rolling section

PROCESS

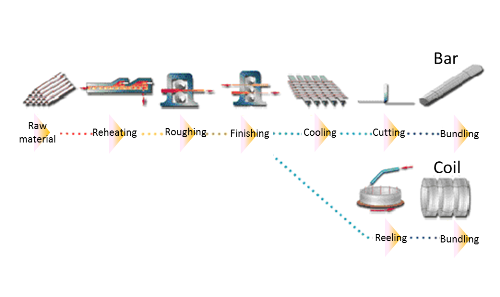

Process flow of rolling mill

Reheated ingots or billets are rolled into various sizes and shapes.

Bars are cut into specified length, wire rods are reeled. Slow cooling in the pit is applicable in case of required.

FACTORY

Rolling section

Round, flat and various shapes of specialty steel and non-ferrous alloy are hot rolled.

In accordance with required mechanical propeties, various rolling technique such as dual phase rolling, thermo mechanical rolling etc. is employed.

Rolling mill |

Manipulator |

Roughing Stand |

Repeater |

EQUIPMENTS

Equipments

| Equipment name | Specification | Quantity |

|---|---|---|

| Roughing stand | 550φTwo-high reverse mill | 1 |

| Mill motor of roughing stand | 750kw Variable speed and reversible A.C. | 1 |

| Intermediate stand | 420φ | 1 |

| Mill motor of intermediate stand | 750kw Variable speed and reversible A.C. | 1 |

| Finishing train | 280φ | 6 |

| Finishing stand | 340φ | 1 |

| Mill motor of finishing train | 1250kw D.C. | 1 |

| Billet reheating furnace | 15m×2m | 1 |

| High-pressure water descaler | 160kg/cm2 | 1 |

| Cooling bed | 70m | |

| Pourling Reel (round, flat) | 2 |

バナースペース

Yachiyo Special Metal Co., Ltd.

730, Owadashinden, Yachiyo,

Chiba prf., Japan 276-0046

TEL +81-47-459-2211

FAX +81-47-459-2215

http://www.y-t-k.com